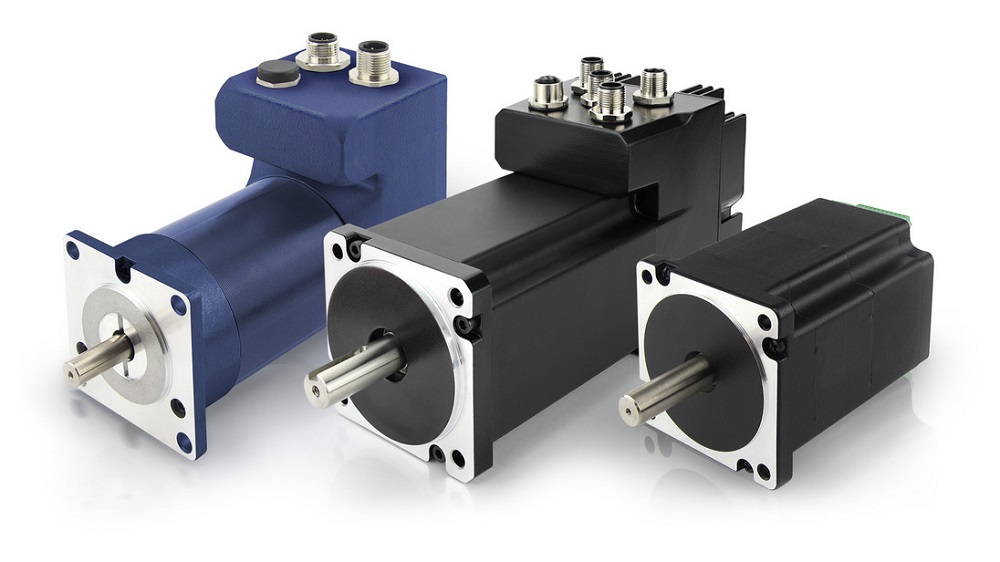

A Servo Motor is an electrical device which can perform linear or rotary motion to an object with incredible precision. The servo motor is a simple motor which runs through a servo mechanism. And, currently, all the applications like a toy, RC helicopters, robotics, and machines are using the working principles of Servo Motor to operate. Servo mechanism is controlled and operated by and with Servo Motor Control Unit (ชุด ควบคุม เซอร์ โว มอเตอร์, which is the term in Thai) or Controller or Driver.

Understand About Servo Motor Controller

The servo motor driver is a circuit that is used to control the position and functions of a servo motor. The servo motor controller is often termed as the Servo Motor Driver and consists of 3 basic units/components. And, those three units are as follows:

- Servo Motor

- Servo Motor Control UnitPower Supply Unit

It can be used to control a single or more than one servo motor. And, in many tools and machines, the controllers/control unit must need to rive more than one servo motor. Because it is designed to perform the specific task as code with the algorithm with Programmable Logic Controller (PLC).

Main & Miscellaneous Components of the Servo Motors Controllers

- Micro-controller

- Power Supply Unit

- Potentiometer

- Connectors like Wires, etc.

How to Control Servo Motor Using Servo Motor Control Unit?

The controlling of the Servo Motor is the main part because it is the working principle of Servo Motors. And, to make work the Servo Motor you need to connect the devices with proper wiring as it has 3 terminals. Those three terminals are Position Signal (PWM Pulses), Power Supply, and Ground.

And, you know PWM pulses with the specific width control the angular position or rotary motion of the Servo Motor. Before that, you need to generate the PWM waveform with the microcontroller or timer. You may also use the PWM block because it fits the need for the application of Servo Motor as it is comparatively more flexible. And, for different widths of PWM Pulses, you will need to program.

And, the program algorithm must be designed in a way that it can control and position either a single or more servo motor. And, to encode the program you need to follow a certain set of rules and steps to accomplish a controlled as well as well-functioning Servo Motor. If it doesn’t work then, you need to do some degree of optimization.